Creating a custom pair of shoes is more than just a design process—it's an intricate journey that takes a product from a mere idea to a finished pair of shoes. Each step in the footwear manufacturing process is crucial to ensuring the final product is of high quality, comfort, and style. From the initial sketch to the final sole, this article will guide you through the steps involved in creating custom footwear, helping you understand how each stage contributes to the finished product.

1. Concept and Design: The Spark of Innovation

Every great pair of shoes begins with a concept. Whether it's a new take on a classic design or an entirely innovative idea, the first step in creating custom footwear is to sketch the initial design. The design process is where creativity meets practicality. Designers must balance style with comfort and functionality.

What happens in this stage?

Brainstorming and Moodboarding: Designers gather inspiration, define the desired aesthetic, and collect materials, textures, and color palettes.

Sketching: A basic sketch of the shoe's appearance, shape, and structure is drawn, helping to visualize the design.

Technical Specifications: Detailed technical drawings are created, including measurements, stitching patterns, and materials.

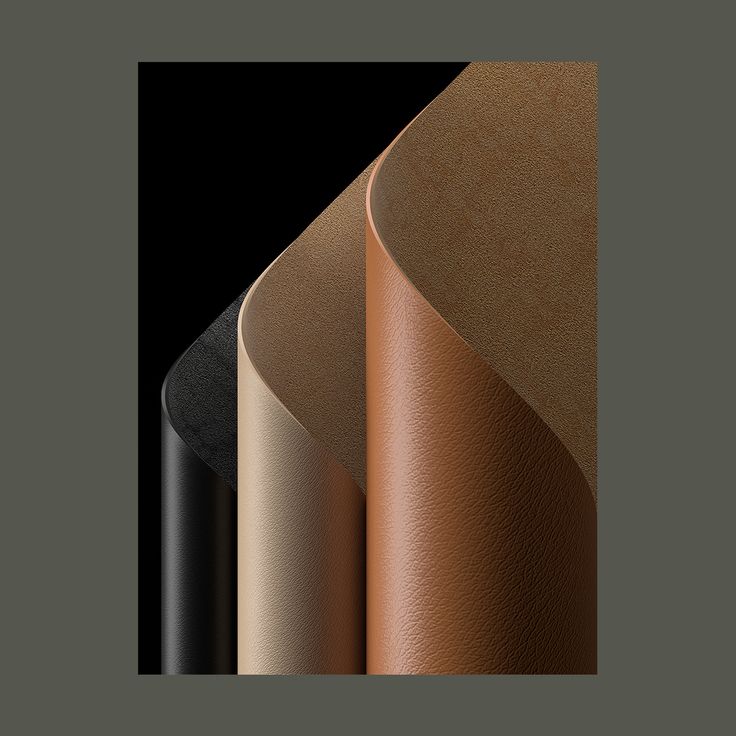

2. Material Selection: Quality and Durability

Once the design is solidified, the next step is selecting the right materials. The materials chosen will define the overall look, feel, and durability of the shoes. Whether you’re creating leather sneakers, dress shoes, or boots, selecting high-quality materials is key to creating a product that’s both stylish and long-lasting.

What materials are typically selected?

Leather: For luxury and comfort, leather is often chosen for its flexibility and breathability.

Suede: A softer, more casual material that adds texture and elegance to footwear.

Synthetics: Eco-friendly or budget-friendly options that still provide durability and style.

Rubber or Leather Soles: Depending on the design, soles are chosen for comfort, flexibility, or style.

3. Pattern Making: Creating the Blueprint

Once the materials are selected, the next step is to create the patterns. Patterns are the blueprints for cutting the various parts of the shoe, such as the upper, lining, and sole. Each pattern piece is carefully measured and adjusted to fit together perfectly when assembled.

What happens in this stage?

Creating 2D Patterns: The designer’s sketches are translated into 2D patterns, which are then used to cut the fabric and materials.

Fitting and Adjustments: Prototypes are often created to test how the pattern fits. Adjustments may be made to ensure the shoe is comfortable and looks as intended.

4. Prototype Creation: Bringing the Design to Life

The prototype is where the design truly comes to life. This first sample helps designers, manufacturers, and clients assess the overall fit, style, and functionality of the shoe. It's a critical step because it ensures that the design works in the real world and that any necessary adjustments can be made before full-scale production begins.

What happens in this stage?

Shoe Assembly: The upper, sole, and lining are sewn and assembled by hand or using machinery.

Fit Testing: The prototype is tested for comfort, durability, and style. Sometimes, minor tweaks are needed in the stitching or materials to achieve the perfect fit.

Feedback: Feedback from the client or internal team is gathered to make any final adjustments to the design or manufacturing process.

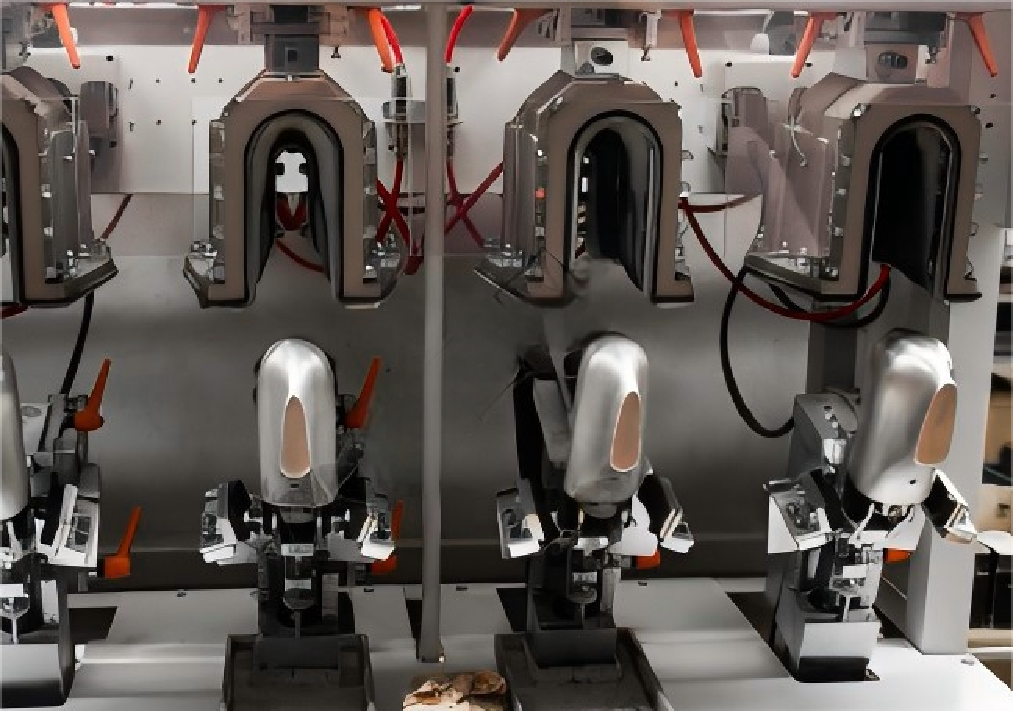

5. Production: Mass Manufacturing the Final Product

Once the prototype has been perfected and approved, the production process begins. This involves manufacturing multiple pairs of shoes, using the same pattern and materials as the prototype but on a larger scale. This stage is where the quality control process becomes crucial, ensuring each pair meets the same standards set by the original prototype.

What happens in this stage?

Cutting the Material: The various materials are cut into the necessary shapes for the shoe components.

Assembly: The shoe is assembled by stitching together the upper, lining, and soles.

Finishing Touches: Any additional elements, such as laces, embellishments, or logos, are added.

6. Quality Control: Ensuring Perfection

Quality control is an essential step in the custom footwear journey. During this stage, each pair of shoes undergoes rigorous inspection to ensure that the shoes are free from defects, fit well, and meet the design specifications. This step guarantees that the custom footwear is made to last and maintains the brand's standards.

What happens in this stage?

Final Inspections: Inspectors check the stitching, finishing, and materials for any flaws or imperfections.

Testing: The shoes are tested for comfort, durability, and fit to ensure they perform well in real-world conditions.

Packaging: After passing quality control, the shoes are packaged carefully, ready to be shipped to the client or store.

Why Choose Us?

1:Global Expertise: Whether you're seeking an Italian shoe factory feel, American shoe manufacturers, or the precision of a European footwear manufacturing company, we’ve got you covered.

2:Private Label Specialists: We offer comprehensive private label shoes solutions, enabling you to create your own shoe brand with ease.

3:Quality Craftsmanship: From custom heel designs to luxury shoe manufacturing, we are dedicated to delivering high-quality products that reflect your brand’s style.

4:Eco-Friendly and Durable Materials: As a trusted leather shoe factory, we prioritize sustainability and durability in every pair of shoes we produce.

Build Your Brand with Us Today!

Take the first step to create your own custom shoes and stand out in the competitive footwear market. With our expertise as a custom shoe manufacturer, we’ll help you transform your ideas into premium-quality, stylish footwear that represents your brand’s unique identity.

Contact us now to learn more about our services and how we can support your journey to becoming a leading name in the world of women’s footwear!

Post time: Feb-19-2025